Example of adoption

AMADA PRESS SYSTEM's products have been adopted by a large number of customers throughout Japan.

Here you can find out how AMADA PRESS SYSTEM has met a wide range of needs, based on actual feedback from customers.

Launch of the vehicle motor housings production line with tandem stamping line and the self-developed washing device.

Takahashi Metal Industries Co., Ltd

Benefits of downsizing by Tandem Stamping Line

MIFUNE Corporation

Improving productivity by promoting automation and robotization

Shiomi Manufacturing Co., Ltd.

Using ultra-precision molds and high-rigidity presses to deal with next-generation parts production

Ogaki Seiko Co., Ltd.

Established high tensile strength steel (HTSS) processing technology prior to other companies and expanded it to overseas factories.

Kanda plant of Topre Kyushu Corporation

A new model from AMADA PRESS SYSTEM improved quality and line efficiency

Mitsui Miike Machinery Co., Ltd.

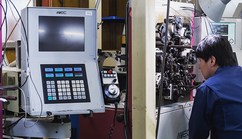

Our changes to Syvec’s control programming helped to improve cycle times for precision processing

Syvec Corporation

Handling a wide range of products in a way that both improves productivity and reduces costs

Yokomori Manufacturing Co., Ltd. Iwaki Factory

Promoting labor reduction and automation to reduce costs

Ito Seisakusho Co., Ltd.

High-precision transfer even in complicated production line environment

Matsuno Press Industry Co., Ltd.

Improving tact time with faster, Steadier and easier-to-use robots

Inagawa Co., Ltd.

Bringing customers japanese quality through simultaneous production around the world

Ikeda Manufacturing Co., Ltd.

Helping to achieve factory automation

Mashima Manufacturing Co., Ltd.

Improved production speed and flexibility/energy-saving for plastic forming

Saitetsu, Inc.

Ensuring steady quality in multiple bending processes for fine springs

Goko Hatsujo Co., Ltd

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.