Our Changes to Syvec’s Control Programming Helped to Improve Cycle Times for Precision Processing

Syvec Corporation

Address: 1000-15 Minamihara, Hirooka-Gobara, Shiojiri City, Nagano Prefecture 399-0704

URL:http://www.syvec.co.jp

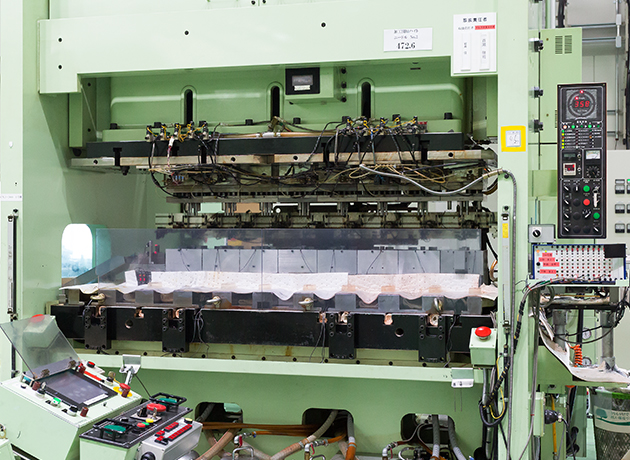

Syvec Corporation is a stamping manufacturer that specializes in progressive pressing technology combining sheet metal forming with a form of cold forging called CFP (cold forging progressive). CFP processing enables complicated, high-precision pressworking of metal products, such as sintering and cutting, that are not possible in conventional stamping processes. The technique is used by many automobile part manufacturers in the production of parts such as gear for the engine and functional parts for the seat frame. Located 11m underground, Syvec’s Dream Factory is set up to create high-precision processing technology, with thorough room temperature and vibration control.

Challenge

Improving processing cycle time

At Syvec, we produce parts for conventional and new automobiles, as well as light electrical parts.

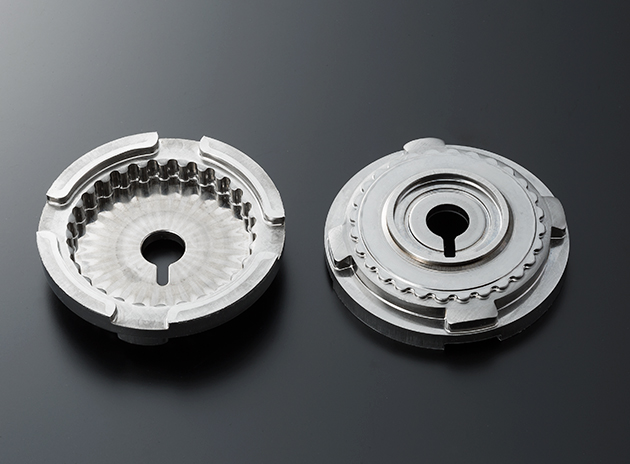

A particular specialty of ours is the production of cycloid gears with heavy gauge coil material parts for CVT in new engines.

Cycloid gears involve molding 3D shapes, a process that is difficult in stamping.

We managed to create them with revolutionary pressing technology that pushes the limits of sheet forging,

but we needed to improve processing cycle times on our production lines while still achieving a high level of quality and processing precision.

Solutions

23% improvement in processing cycle times after change in control

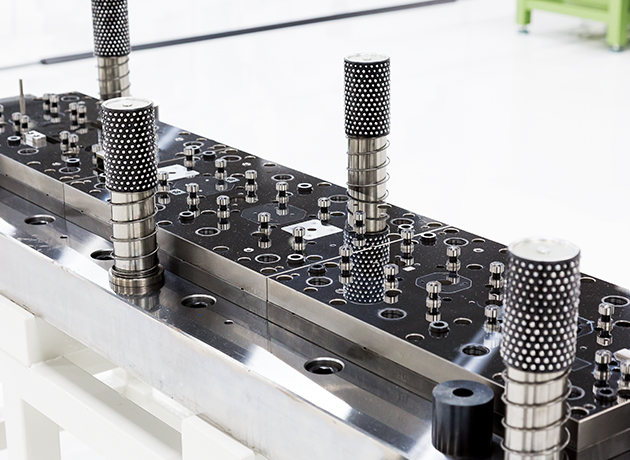

Implementing AMADA PRESS SYSTEM's products dramatically improved our productivity thanks to new features such as touch panels and functions for displaying the job number and standard setting reference.

The RSN robot line for multi-process conveyance was also full of options for adjusting and changing the control programming,which enabled us to shorten our processing cycle time for cycloid gears with heavy gauge coil material from 3.7 seconds to 3.0 seconds - a 23% improvement.

The biggest reason why we adopted AMADA PRESS SYSTEM's products was because of how well they fit our company’s needs - they are extremely user-friendly and enable a follow-up framework for the whole company including the technical staff.

We are developing sales routes overseas in addition to our domestic sales routes to get as many people using our proprietary technology as possible.

We are also working to improve each individual staff member’s skills so that they can come up with the perfect solutions to our customers’ problems.

We will work together with our affiliated companies to find solutions that our customers can be satisfied with and make sure that our Dream Factory turns out manufactured products that will appeal to our many Syvec fans all over the world.

- The product features, services and other information described here are correct as of Jun 2016.

- Please do not directly contact the company described here.

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.