Helping to achieve factory automation

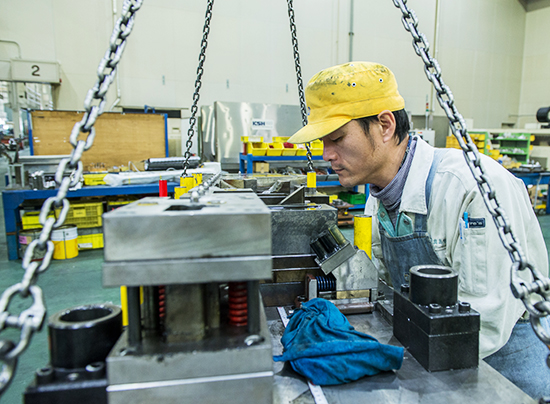

Mashima Manufacturing Co., Ltd.

Head Office: 1191-19 Oaza Kami-Izumi, Kuboizumi-machi, Saga City, Saga Prefecture 849-0902

URL:http://mashima-ss.co.jp

Ever since it was first established, Mashima Manufacturing has met the many needs of each new era with innovative technology and ideas. The company does not confine itself or its theories to the field of presses - it is continuously working on projects concerning all forms of manufacturing, including mold design, planing, sheet metal processing and welding. Mashima Manufacturing works to perform pressworking even for parts that are usually unsuitable for pressing, and performs a series of processes from proposals of designs that suit each client’s image to mass production.

Issue and solution 1

Quick response to frequent layout changes and process changes at the production site

Mashima Manufacturing frequently remodels and moves its production equipment and changes its processes in order to meet its clients’ diverse needs.

The company used another company’s feed equipment until last year, but was dissatisfied with that manufacturer.

This prompted Mashima Manufacturing to introduce 5 straightener/feeders and 12 robot systems (one 5-machine line and one 7-machine line) from AMADA PRESS SYSTEM last year.

The company was impressed with our accurate support system and excellent follow-up service - two strong points of ours.

We also quickly responded to a simultaneous remodeling of three machines.

Simplification of production processes and increase in production line speed

The company had been stressed by factors such as the speed of the machines and processes such as line adjustment and sending feed commands to the press.

After introducing machinery from AMADA PRESS SYSTEM last year, Mashima Manufacturing succeeded in simplifying its production processes, with the following effects:

| Coil line (straightener/feeder) |

Accurate commands can be given to the press, allowing stress-free operation. The double uncoiler design has resulted in more efficient coil changing in the pre-arrangement process. The touch panel also makes the machinery easy to operate, and makes the error display easy to understand. Operation has been issue-free since the introduction of the machinery, with no malfunctions. |

|---|---|

| Robot system line | The production speed is now higher, with the daily production rate around double what it used to be. The lines can also be adjusted quickly, as the line height for each mold can be remembered. |

Mashima Manufacturing plans to continue applying its top-notch technical capabilities to a wide range of fields, with the ultimate goal of making all of its machinery fully automated. AMADA PRESS SYSTEM will do everything possible to help Mashima Manufacturing achieve these goals.。

- The product features, services and other information described here are correct as of June 2016.

- Please do not directly contact the company described here.

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.