Using ultra-precision molds and high-rigidity presses to deal with next-generation parts production

Ogaki Seiko Co., Ltd.

Location: 32-1, AsaNishi, Ogaki-shi, Gifu Prefecture,503-0945

URL:http://www.ogakiseiko.co.jp/

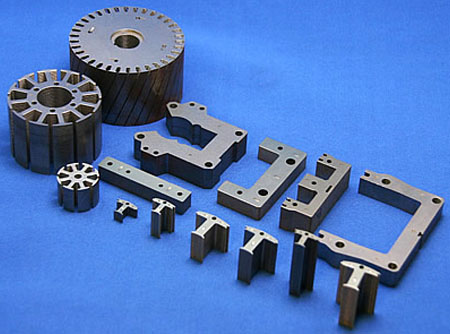

Ogaki Seiko Co., Ltd. has the world's leading technology in the field of ultra-precision mold design and production. Its affiliated company Seiko Hi-tech Co., Ltd. builds a consistent production system of high-value-added electronic equipment parts, auto parts, and telecom equipment parts by using self-developed molds, and is committed to promoting the next generation of mass production of components, the establishment of new processes, and try new materials, stamping processing of difficult materials.

Headed by hard disk (HDD) parts that only four companies can produce worldwide, such as relay switches for next-generation cars, production technology for electric compressor parts, and extremely micro-punching molds for ceramic thin plates for electronic machines , Honeycomb ceramic molds for exhaust purification filters and other high value-added technologies, so that Ogaki Seiko Co., Ltd. will not fall into cost competition with overseas.

President Ueda served as the chairman of the Japan Die&Mold Industry Association for 11 years from 2001 to 2012, and was awarded the "The Order of the Rising Sun, Gold Rays with Neck Ribbon." in the spring of 2013.

Challenge

In the general trend of increasing accuracy requirements for automotive electronic parts and telecom equipment parts, it will naturally put high standards on many aspects such as molds, presses, and factory environments.

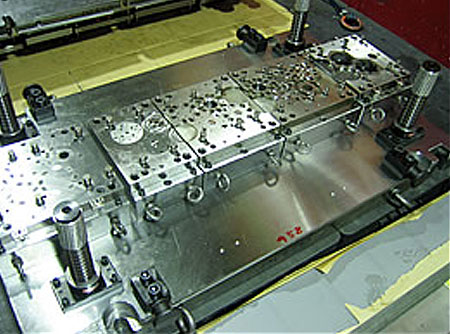

At the same time, the cold forging technology and crushing processing must be used for the production of the above precision parts. Therefore, ultra-precision molds and high-rigidity presses have become necessary in this processing field.

Solution

In the field of electronic components, the processing of new materials, plate thicknesses and quantities is increasing day by day, and the production volume of existing press equipment cannot meet the market demand.

At present, the Wanouchi Plant No. 2 already has six high-rigidity and high-precision knuckle joint press (PDL). However, considering the needs of electronic equipment parts related to 5G technology, and automotive sensors in the future,5 high-rigidity SDEGORIKI series servo presses were introduced when building Ogakinishi Plant.

Among them, 2machines are in Ogakinishi Plants (SDE-1515GORIKI×2 sets), and 3 machines are in Wanouchi No.2 Plants (SDE‐2017GORIKI×2 sets, SDE-1515GORIKI). The high rigidity servo press offers high productivity and stability of product accuracy.

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.